Thermoforming is a technique that is particularly suitable for small and medium production runs, as well as for large parts.

Technics

Known for many years for its cutting-edge expertise in thermoforming and other plastic processing techniques, Plastisart offers you over 50 years of experience in the manufacture of plastic parts and components in Belgium and France.

-

-

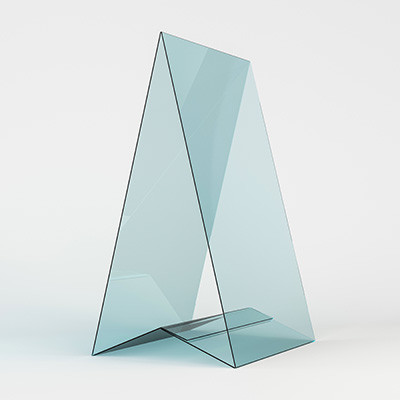

Blow moulding and draping of plastic are processing techniques that enable the creation of curved, concave and convex parts.

-

Hot forming of plastic offers exceptional flexibility for creating curved or bent plastic parts with unrivalled precision.

-

Contactless blow thermoforming offers exceptional optical clarity without distortion, meeting the most stringent industry standards.

-

With unlimited versatility and express delivery, we offer superior quality tailored to various industrial sectors.

-

RIM injection offers an economical alternative for the production of large plastic parts and technical components.

-

Plastisart excels in bonding Plexiglass for a variety of applications, offering optimal optical quality and exceptional strength.

-

Hot air plastic welding: Precise, durable and versatile assembly.

Extensive expertise in plastic processing techniques

From thermoforming, bending, drape forming and blow moulding to finishing coatings and 3- and 5-axis machining, we offer you the optimal solution tailored to your situation and budget.

Plastisart also has expertise in bonding Plexiglas and plastic welding, guaranteeing customised plastic solutions of the highest quality. Whatever your project, Plastisart offers you the solution that precisely meets your needs in terms of both functionality and performance.

Would you like to call on Plastisart, your partner for customised plastic solutions in Belgium and France?

Plastisart is at your disposal to study your projects and offer you solutions tailored to your specific needs. Contact us now via our online form or by phone to find out more about our services.