Non-contact blow thermoforming is an extremely efficient technology for manufacturing transparent...

Bending / Hot forming

Hot forming of plastic offers exceptional flexibility for creating curved or folded plastic parts with unrivalled precision. This technique, often referred to as ‘hot bending’, can be used to produce customised casings, ducts, fittings and much more. Plastisart, a specialist in plastic processing in Belgium and France, has mastered this method to turn your ideas into plastic with precision and quality.

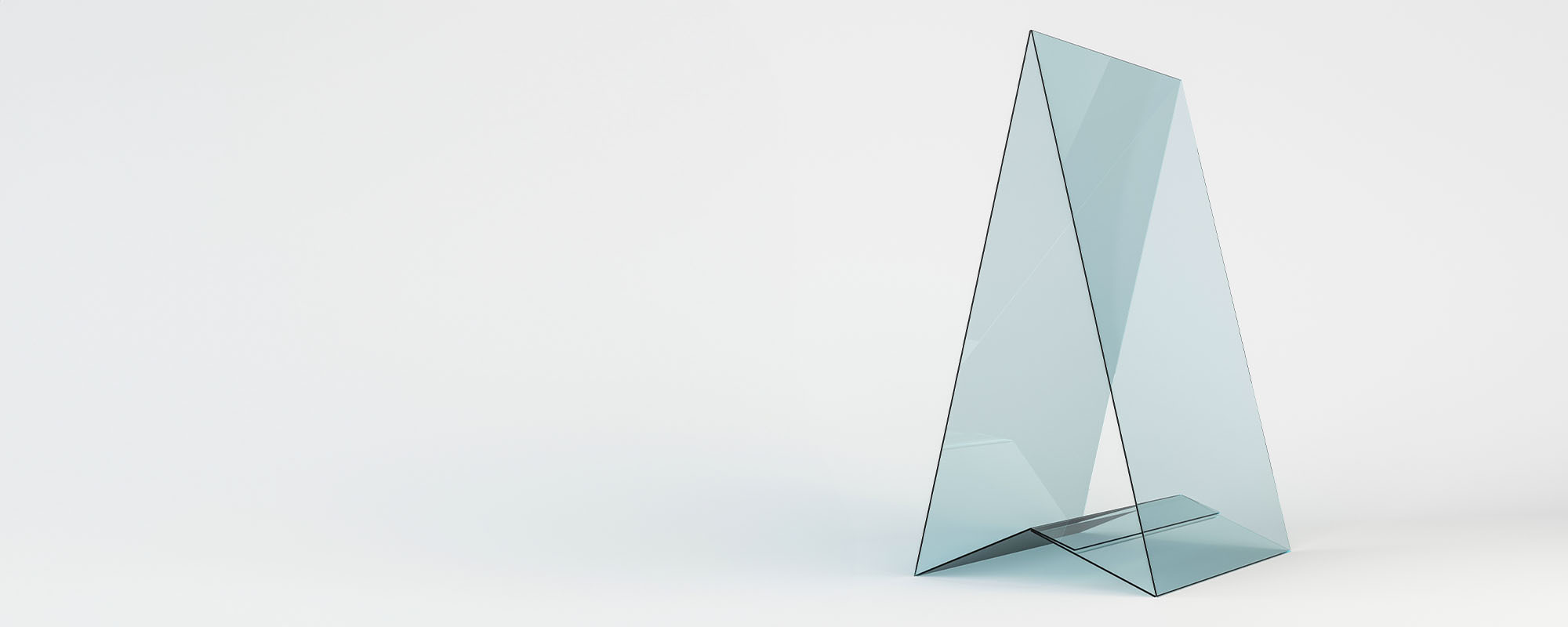

Some images of our hot bending service

Discover our service in pictures:

Hot forming

Hot forming of plastic is a fascinating processing technique that opens up endless possibilities for plastic design. It relies on the flexibility of a plastic sheet that can be bent or curved at will using heating wires or resistors, giving it precise curves or angles.

This method, often referred to as ‘hot bending’ or ‘hot forming’, is the art of precision and flexibility. It is commonly used to shape long straight sections of plastic into curved or bent parts, creating clever enclosures, smart ducts, custom fittings, and much more. It allows for unmatched precision in the production of plastic parts that meet the most specific requirements.

Imagine the endless possibilities of hot forming to bring your plastic ideas to life. At Plastisart, we master this art and precision technique to bring your 3D concepts to life. Our experts create plastic parts that exactly match your specifications, while delivering the quality and precision you demand. Trust Plastisart for all your plastic hot forming needs and discover how we can bring your most ambitious projects to life.

Applications of bending and hot forming

- Custom ducts: Hot forming is ideal for creating custom plastic ducts used in air conditioning, ventilation and heating systems.

- Vehicle interior trim: Car interior trim, such as door panels and dashboard trim, can be precision-made using this technique.

- Housings and enclosures: Protective housings for electronics, mechanical component housings, and equipment enclosures are commonly manufactured using hot forming.

- Custom medical equipment: Plastic parts used in the medical industry, such as medical device holders, are often created using hot forming.

- Pipe fittings: Curved or angular sections of plastic piping, tailored to specific requirements, can be hot formed.

- Laboratory equipment: Laboratory components, such as tanks, instrument housings, and analysis parts, are manufactured using hot forming.

- Custom architectural elements: Architectural elements, such as facade panels, decorative elements, and special designs for interior spaces, can be custom-made using this technique.

- Parts for the catering industry: Special shapes of plastic parts, such as storage trays, shelves, and food service items, are produced by hot forming.

- Industrial components: Plastic parts used in various industrial applications, from machine supports to control panels, are manufactured using this technique.

- Sports and leisure equipment: Components for sports equipment, such as surfboard shells or panels for camping equipment, are designed using thermoforming.

Materials used in bending and hot forming

- Polystyrene (PS): Trays, display stands, packaging components.

- Polypropylene (PP): Storage boxes, foldable signage, consumer products.

- Polycarbonate (PC): Curved glazing, protective windows, interior design components.

- Polyethylene terephthalate (PET): Customised packaging, food containers.

- Polymethyl methacrylate (PMMA, acrylic): Curved glazing, interior design elements, display stands.

- Polyurethane (PU): Foldable coatings, customised foams, cushioning elements.

- Polyvinyl chloride (PVC): Curved construction profiles, flexible signage, decorative elements.

- Acrylonitrile butadiene styrene (ABS): Curved automotive parts, mechanical components, customised products.

These examples illustrate the versatility of plastic hot forming, which allows customised parts to be created for a variety of industrial and commercial applications.

Contact our hot forming experts in Belgium and France

If you have any questions or require further information, please contact our team of specialists, who are here to help. We are available by phone or via the online form.