Non-contact blow thermoforming is an extremely efficient technology for manufacturing transparent...

Interior design of medical vehicles Customised design for demanding environments

Plastisart, a specialist in custom manufacturing, provides personalised solutions to meet the needs of its customers, particularly those specialising in the fitting out of vehicles adapted to harsh environments, such as conflict zones, bush tracks and the mining industry. Recently, Plastisart received a specific request to design and manufacture furniture for the interior fittings of medical vehicles in tropical areas.

A tailor-made solution adapted to extreme conditions

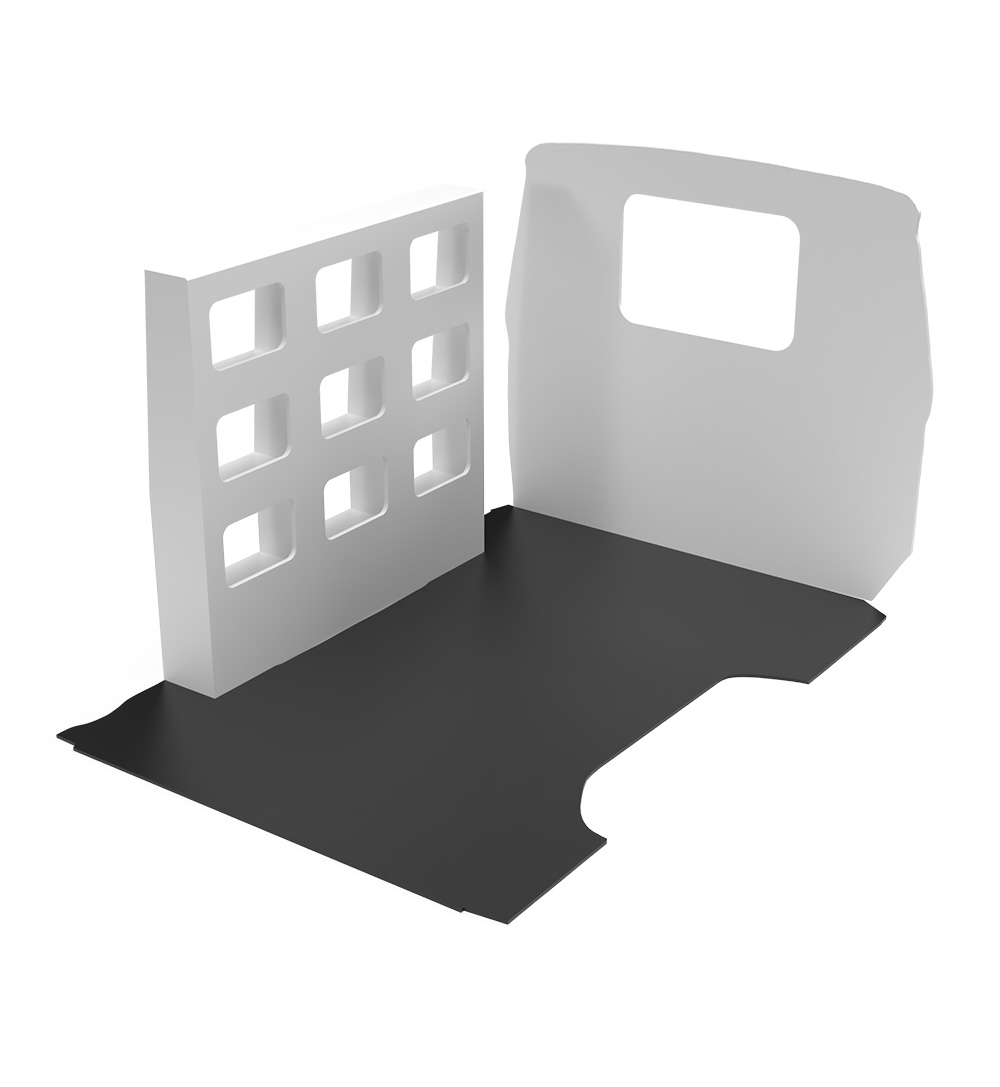

The Plastisart team designed and manufactured various customised components to meet the specific needs of this demanding environment. A storage unit, a bench seat, the floor covering and a sectional panel separating the passenger compartment from the medical area were produced in our workshops. Honeycomb polypropylene, VikuFoam, was chosen for its lightness, UV resistance and closed-cell structure, which guarantees high strength and easy cleaning.

Expert production process: machining and welding

Each component was carefully manufactured using machining and hot welding techniques suitable for VikuFoam. The floor and sectional panel were milled to ensure a precise and robust finish, perfectly suited to the harsh conditions in which these medical vehicles are used.

A durable and functional solution

The furniture designed in this way provides an interior environment that is robust, easy to clean and perfectly suited to the specific requirements of these vehicles. This customised solution demonstrates Plastisart's commitment to meeting the specific needs of its customers by offering personalised solutions adapted to the most demanding conditions.

Medical environments and the chemical industry: adaptability of materials

In addition, this production method is ideal for manufacturing furniture for demanding medical environments or specialised furniture for the chemical industry. The materials used, such as polypropylene and polyethylene, allow for the creation of watertight assemblies that are resistant to a wide range of solvents and chemicals, ensuring increased durability and safety in sensitive environments.

Contact us to find out how we can meet your specific custom manufacturing needs, guaranteeing quality products without compromising on delivery times.